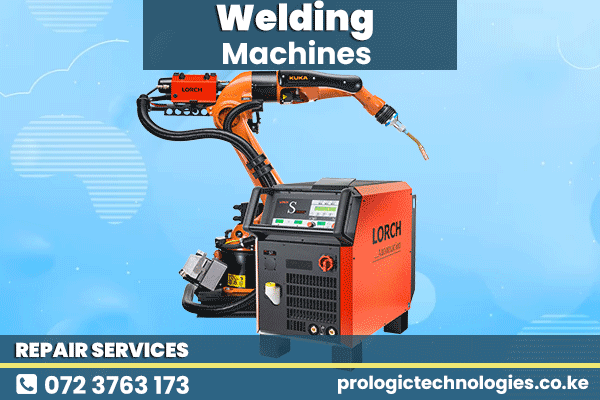

Welding Machine Repair by Prologic Technologies in Nairobi

Welding Machine Repair is a specialized service offered by Prologic Technologies in Nairobi, catering to the needs of various industries and workshops. With years of experience and expertise in the field, Prologic Technologies has become a reliable name when it comes to repairing welding machines of all types and brands.

Welding Machine Repair at Prologic Technologies encompasses a wide range of services, including troubleshooting, diagnosis, and efficient resolution of issues. Whether it’s a minor glitch or a major malfunction, their team of skilled technicians is well-equipped to handle all kinds of challenges with precision and speed.

When your welding machine faces problems such as faulty electrical components, broken circuitry, or any mechanical issues, it can significantly hamper your work efficiency. Understanding the urgency of such situations, Prologic Technologies ensures prompt responses to repair requests, minimizing downtime and maximizing productivity.

The welding machine repair process starts with a thorough inspection to identify the root cause of the problem. Once the issue is pinpointed, their expert technicians utilize state-of-the-art tools and technologies to execute the repairs. Prologic Technologies maintains a vast inventory of genuine spare parts, ensuring that any damaged components are replaced with high-quality, original parts to restore the machine’s optimal performance.

Moreover, Prologic Technologies offers welding machine repair services for various types of welding machines, including arc welding machines, MIG/TIG welding machines, spot welding machines, and more. Their team’s proficiency extends to both conventional and advanced welding equipment.

Customer satisfaction is at the core of Prologic Technologies’ values, and they take pride in providing top-notch welding machine repair solutions. With their focus on quality workmanship, attention to detail, and commitment to customer service, they have garnered a loyal clientele across Nairobi and its surrounding regions.

In addition to welding machine repair, Prologic Technologies also offers maintenance services to prevent potential issues and keep your welding equipment in excellent condition for extended periods. Regular maintenance can not only enhance the lifespan of your welding machines but also save you from costly breakdowns and repairs in the long run.

Whether you own a small welding shop or manage a large industrial facility, Prologic Technologies’ welding machine repair services are tailored to meet your specific needs. Their transparent pricing, quick turnaround times, and skilled technical support make them the go-to choice for welding machine repairs in Nairobi.

In conclusion, if you are in Nairobi and seeking reliable and efficient welding machine repair services, Prologic Technologies stands as a reputable and competent provider. Their dedication to excellence and customer satisfaction ensures that your welding machines are in safe hands. Trust Prologic Technologies to get your welding machines up and running swiftly and effectively, so you can resume your welding operations with minimal disruptions.

Common Welding Machine Problems and Repair Solutions

Welding machines, like any other equipment, can encounter various issues over time. Understanding these common problems and their repair solutions can help you address them promptly and keep your welding operations running smoothly. Here are some typical welding machine problems and their respective repair solutions:

1. Poor Weld Quality: Issue: When the weld quality is subpar, it may indicate inconsistent arc, uneven beads, or lack of penetration.

Repair Solution:

- Check the welding machine’s power supply and ensure it’s stable and providing the correct voltage and current.

- Clean the welding electrode or wire to remove any contaminants or oxidation.

- Adjust the welding parameters, such as voltage, amperage, and travel speed, to match the material and thickness being welded.

- Inspect the welding cables and connections for any damage or loose connections.

2. Overheating: Issue: If the welding machine becomes excessively hot during operation, it can lead to overheating and potential damage.

Repair Solution:

- Check if the cooling system (fan or water cooling) is functioning correctly, and clean any debris or dirt that might be obstructing airflow.

- Ensure the workspace has proper ventilation to dissipate excess heat.

- Reduce the welding machine’s duty cycle by allowing it to cool down between extended welding sessions.

3. Electrode Sticking: Issue: The welding electrode may stick to the workpiece, making it difficult to strike or maintain an arc.

Repair Solution:

- Verify that the welding machine’s polarity settings are correct for the electrode being used (DC+ or DC-).

- Ensure the workpiece surface is clean and free from rust, oil, or paint, which can cause the electrode to stick.

- Adjust the arc length to a suitable distance, typically 1.5 times the electrode diameter.

4. Erratic Arc: Issue: The welding arc may flicker or become unstable during welding, leading to inconsistent welds.

Repair Solution:

- Examine the welding cables and connections for any damage or loose connections that could disrupt the current flow.

- Check for a contaminated electrode or filler wire, and clean or replace it if necessary.

- Adjust the welding machine’s arc control settings to stabilize the arc.

5. Wire Feeder Problems (for MIG/MAG Welding Machines): Issue: Wire feed issues can result in irregular and unreliable filler wire delivery.

Repair Solution:

- Inspect the wire feeder system for any kinks, bends, or obstructions in the wire pathway, and straighten or clear them as needed.

- Lubricate the wire feeder to ensure smooth and consistent wire feed.

- Check the drive rolls for proper tension and alignment, and adjust if necessary.

6. Gas Flow Problems (for TIG and MIG Welding Machines): Issue: Insufficient or excessive shielding gas flow can lead to poor weld quality and contamination.

Repair Solution:

- Check the gas supply and regulator for any leaks or malfunctions, and repair or replace them as required.

- Clean the gas nozzle and ensure it’s properly installed.

- Adjust the gas flow rate to the recommended levels for the specific welding process and material.

Note: While some welding machine problems can be addressed through basic troubleshooting, complex issues may require the expertise of a qualified technician. Regular maintenance and periodic inspections can also help prevent potential problems and extend the lifespan of your welding machine.